by Aldo Benedetto ZOTTI*, Anna BORRIELLO*, Simona ZUPPOLINI*, Mauro ZARRELLI* e Domenico ACIERNO+

The European industry is currently a world leader in aviation and to maintain its leadership position and competitiveness in the dynamic global market, it must develop quickly and efficiently high quality products. Industrial competition is becoming fiercer not only from established regions, such as the USA and China, but from new emerging challengers, such as Brazil, Canada, etc. Nowadays, with the advent of these concurrent nations the competitiveness of a country is measured considering it technological leadership and innovation ability, with particular attention to the reduction of costs and environmental pollution.

Composite materials play a key role in aerospace field because allow to develop multifunctional structures with high specific properties, with consequent reduction of weight, increase of fuel efficiency and abatement of CO2 emissions. Despite their outstanding properties, composite materials suffer of impact with foreign objects, such as hail, stray debris and birds (the so-called “bird-strike” phenomenon): that can lead to unpredictable localized damages, with reduction of the composite material strength and, consequently, of the whole structure.

The Institute of Polymers, Composites and Biomaterials (IPCB) of the National Research Council (CNR) from Portici (Italy) participated in several specific programs for the aerospace and automotive sectors, with the aim of developing novel functionalized polymer matrices with improved impact properties for long fiber reinforced composite by using micro- and nanofillers such as, carbon nanotubes and nanofibers, graphene and graphite, as well as hyperbranched polymers and core/shell nanoparticles specifically synthetized in lab. IPCB, member of CRdC Nuove Tecnologie per le Attività Produttive scarl, can boast a significant experience in development and characterization of polymer matrix composite materials in the aeronautical and aerospace field.

IPCB, between 2015 and 2019, took part to the “EXTREME” European Project, whose purpose was developing novel material characterization methods, in situ measurement techniques, material models and damage simulation methods for the design and manufacture of aerospace composite structures under EXTREME dynamic loadings.

In the framework of the project, new nanocomposites were developed and employed to manufacture hierarchical composites, i.e. composites where the matrix itself is modified with synthetic particles able to absorb the impact energy. These innovative composites, together with the traditional composites reinforced with long basalt fibers, were tested, using novel characterization technique in extreme loading conditions, and validated in order to obtain the parameter needed for the numerical models developed in parallel.

During the project significant results were obtained, leading to the publication of numerous papers on international journals; moreover, many technologies for the monitoring of damages and the study of the mechanisms induced during the shock wave formation and propagation were patented and commercialized.

3D models for damage simulations were developed in order to make the design process of aeronautical structure subject to extreme loadings faster, precise and cheap, eliminating (in some cases) long experimental campaign.

The EXTREME project involved 14 European partners including some of the world's leading aerospace industries (Rolls Royce, Agusta Westland, Israeli Aerospace Industries, Dynamore and MSC software), universities and a research centre (Delft University of Technology, Ghent University, Brunel University, University of Patras, National Research Council), and SMEs (Dynamore, Dynawave, Technobis Fiber Technology).

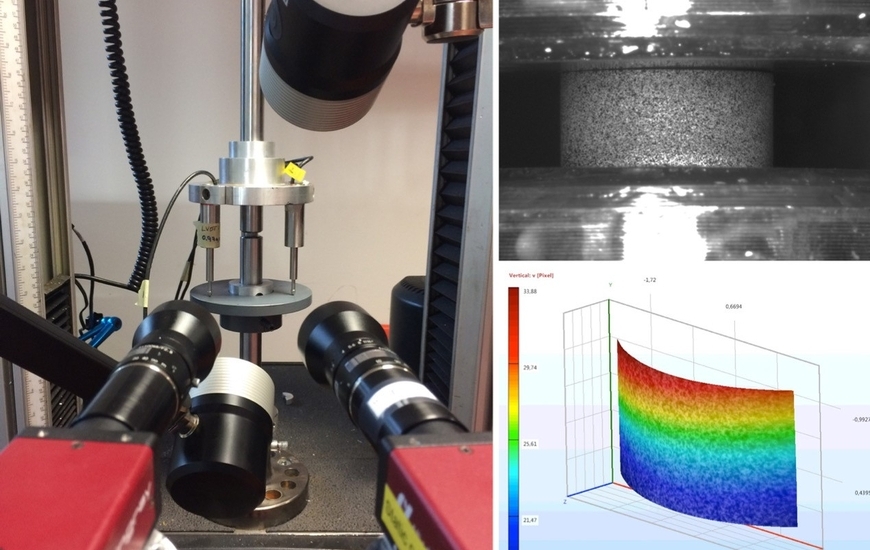

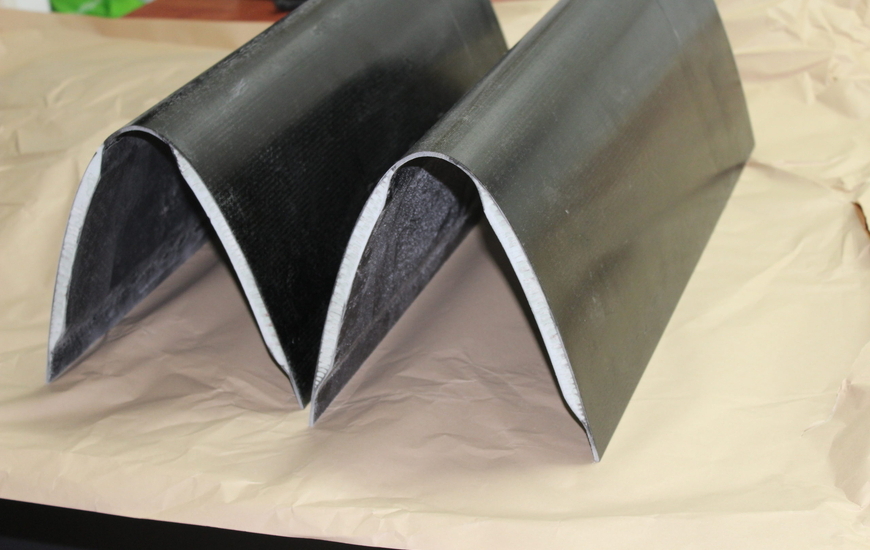

In the first image, Leading edge demostrators (courtesy of "Extreme Project"); in the second one, High Strain Compression test set-up and Digital Image Correlation system (courtesy of Ugent University, Belgium)

* Researchers at the CNR-IPCB of Portici (Naples)

+ Director of CRdC Nuove Tecnologie per le Attività Produttive scarl

-

-

27 January 2022