As part of their mission to reduce waste and production time in large composite structures, Curve Works has been pushing forward with the composite panel assembly approach. As the name suggests, the approach is to assemble the structure from panels rather than in a single shot in a large mould.

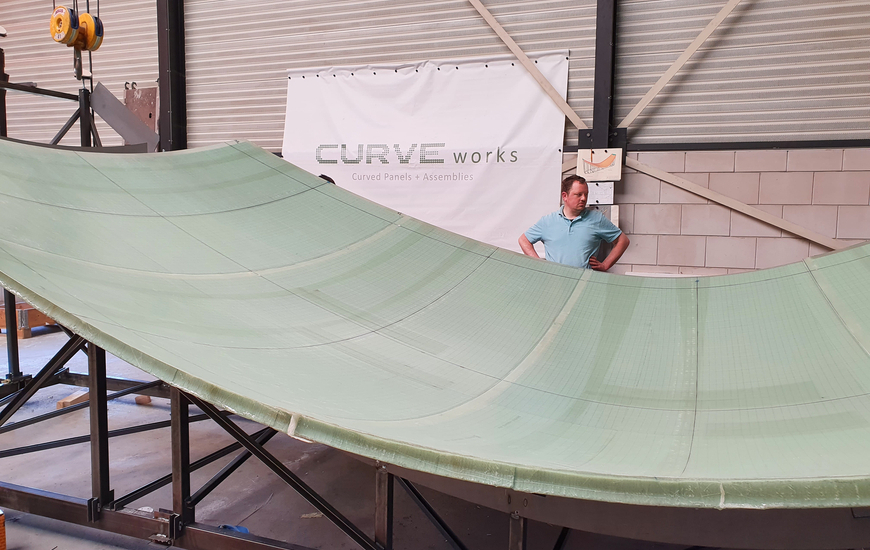

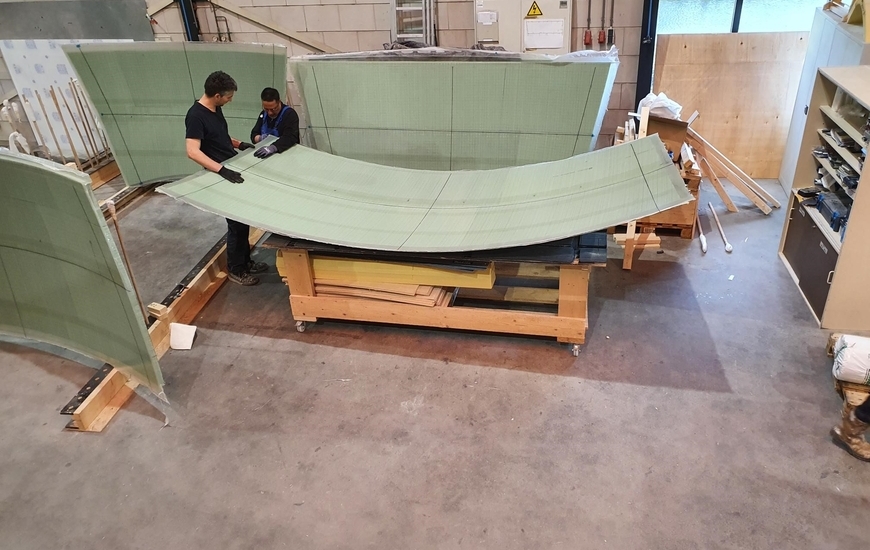

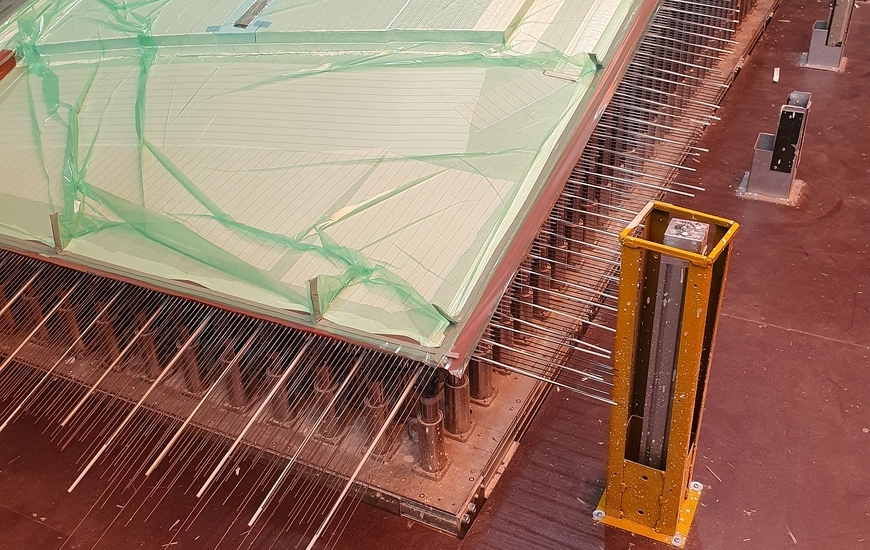

To demonstrate the approach, Curve Works has manufactured a series of uniquely doubly curved composite sandwich panels using their automated adaptive mould both to thermoform the 3D core kits and infuse the parts. The panels, ranging in size up to 4 m x 1.6 m were assembled on a metal-frame jig and bonded together using their proprietry technology. The result is an airtight structure of 10 m length, 4 m width and 3 m height.

Material choice for the structure was carefully considered as well, featuring both Gurit’s Kerdyn Green PET structural foam and Ampro BIO.

The whole process from panel production to structural assembly took only 14 working days. “It’s a major milestone for us to demonstrate the modular building value in a real life application,” Tahira Ahmed, co-founder of Curve Works, says. “Compared to manufacturing using a large mould, our figures show that we can reduce cost by 40%, lead-time by 50% and, importantly, material use by at least 70%”.

The panel assembly approach together with adaptive mould technology allows Curve Works to be very flexible in both shape and size of the final part. “We have a production technology here that allows us to cover the customer needs in terms of size and shape without the costs and tooling waste increasing exponentially as well”.

PHOTOS (by Curve Works):

Figure 1: curved sandwich panel production on an adaptive mould

Figure 2: a cured panel is lifted from the adaptive mould

Figure 3: the panels are assembled on a simple steel-frame jig

Figure 4: the assembled airtight doubly curved shell structure

-

-

08 June 2021