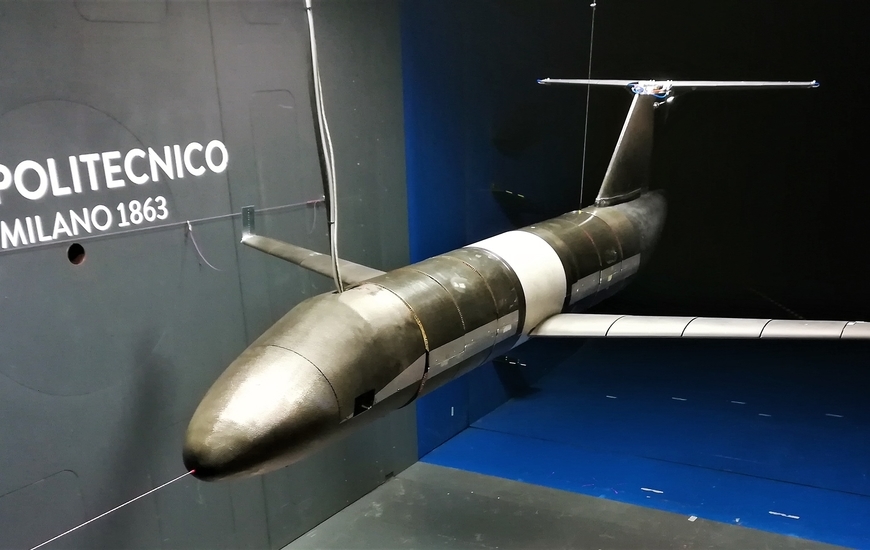

CRP Technology collaborated with the Department of Aerospace Science and Technology of the Politecnico di Milano (PoliMi) on the construction of parts for the aeroelastic wind tunnel demonstrators for “Aeroelastic Flutter Suppression (AFS)” e “GLAMOUR” projects.

The AFS project was launched by PoliMi and the University of Washington to test different active control system technologies aiming to attain Active Flutter Suppression. The GLAMOUR project was focused on technological optimization and experimental validation of Gust Load Alleviation (GLA) control systems for an advanced Green Regional Aircraft manufactured by Leonardo Aircraft Division.

The contribution of CRP Technology involved the manufacturing of the external aerodynamic segments of the two wind tunnel demonstrators for both projects.

CRP Technology used professional 3D printing (selective laser sintering technology) and Carbon-composite Windform® XT 2.0 from its range of composite materials for LS, the Windform® TOP-LINE.

Windform® XT 2.0 was also used by CRP Technology to create the horizontal tail of the wind tunnel demonstrator for the AFS project.

-

-

29 June 2019