Moulding

-

-

The company has successfully completed its tests on a technology that bonds carbon fiber reinforced plastic (CFRP) aircraft mock-up structures almost three times faster than conventional approaches

-

-

hese solutions are designed to improve efficiency, process control, and performance for thermoset and thermoplastic composite applications

-

-

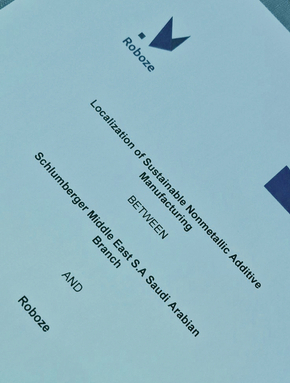

Roboze’s technology enables metal replacement and the on-demand production of high-performance components

-

-

Japanese Nannen-sei certification for ULTEM™ 9085 produced with Roboze Additive Manufacturing solutiNew safety standards for additive manufacturing in the Japanese railway sector

-

-

The aim is to to establish Bahrain’s first industrial facility dedicated to advanced additive manufacturing

-

-

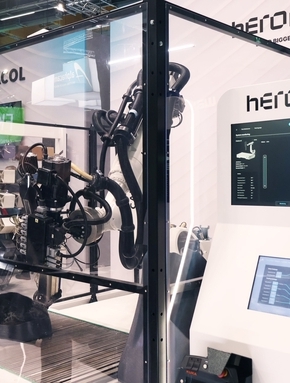

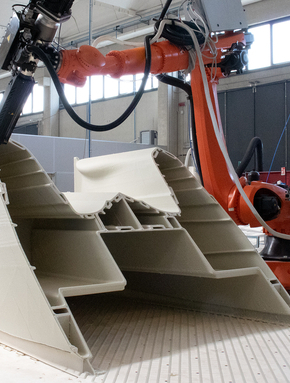

Caracol showcases real, production-proven LFAM applications and AI-driven software at Formnext 2025

-

-

Since the beginning of this year, Solize Partners has been the distributor of Roboze in Japan

-

-

On 21–22 January 2026 at Motorworld in Munich, an event to explore how inkjet and deposition technologies are reshaping manufacturing

-

-

The UAE is investing heavily in economic diversification and the creation of an industrial ecosystem focused on sovereign production

-

-

The new headquarters is built to bring advanced manufacturing closer to customers

-

-

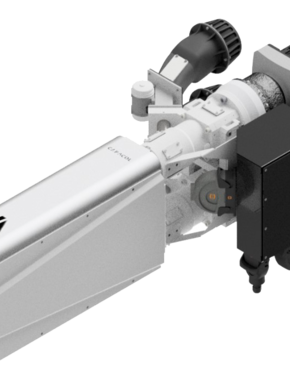

New extension to product offering improves and simplifies post-processing time by reducing workflows to a single step

-

-

On June 27th, 2025, Rimas Engineering, in collaboration with its partner Treddy, is organizing the 5th edition of the event

-

-

This collaboration emphasizes the key role of robotized processes as a game changer in enabling the widespread industrial adoption of needs-based advanced manufacturing

-

-

Interview with Phil DeSimone, Ceo of Carbon

-

-

Ferretti Group chose to commission Caracol for the realization of the first 3D printed air grilles for the Pershing GTX116

-

-

The company has established itself as a trusted partner for problem-solving and delivering high-performance solutions in the space and aerospace sectors

-

-

The motorsport team renews its technical partnership with Roboze for three years

-

-

The new solution can process two materials simultaneously thanks to a double chamber and custom nozzles

-

-

The collaboration between V2 Group and Caracol AM strengthens their leadership in nautical and naval innovation

-

-

The MoU, which was signed at the In-Kingdom Total Value Add (IKTVA) 2025 Forum and Exhibition, sets the stage for advancements in the local manufacturing of non-metallic parts

-

-

The “ARGO 500 HYPERSPEED” will also be installed in our Toyota Plant. Applications for verification and manufacturing support

-

-

Active since 2022, this partnership now extends to new markets, including Germany, Denmark, Finland, Sweden, Spain, and South Africa, in addition to the previously covered territory of Norway

-

-

The Italy-based company specializing in 3D printing services has expanded its suite of production and post-processing capabilities

-

-

Innovative solution created to address market requirements for faster printing with a larger print bed

-

-

Roboze introduces the motto Your Production Power, a clear reference to the software's ability to boost production

-

-

The Italian company will showcase 3D printed parts made from Windform composites using the Selective Laser Sintering (SLS) process

-

-

This collaboration marks a significant breakthrough in the use of advanced production technologies in international automotive competitions

-

-

Caracol’s partnership with KUKA represents the culmination of years of close collaboration, during which Caracol developed and industrialized their robotic AM platform using KUKA’s six-axis robotic arms for kinematics

-

-

This collaboration has resulted in the team's historic win as the first Italian team to secure victory at the prestigious Formula Student Austria competition

-

-

Hitachi Rail has chosen the Roboze Argo 500 solution to operate in its high-tech factory in Naples, in Italy, and its new digital, state-of-the-art rail factory in Washington County, Maryland