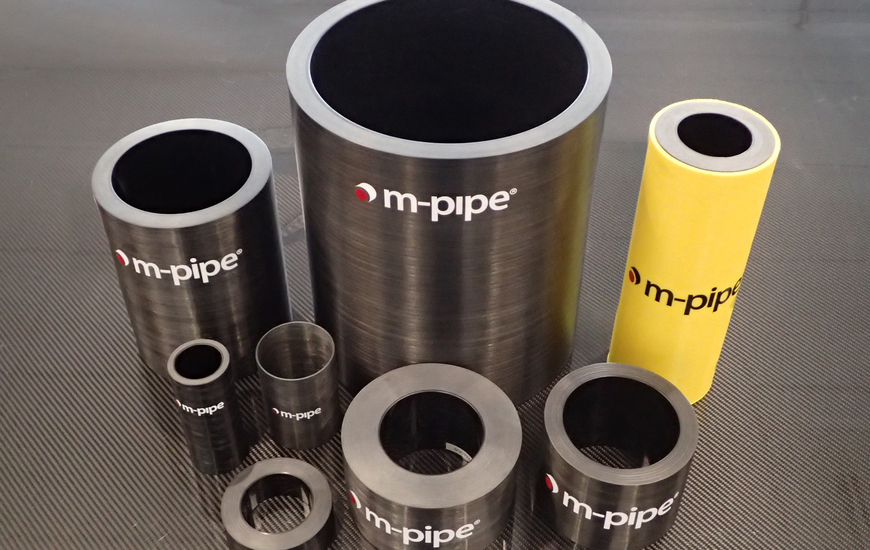

Magma Global m-pipe®, based on high-performing VICTREX™ PEEK thermoplastic composite, has recently achieved the world’s first qualification for a subsea pipe product under DNVGL-RP-F119 for Thermoplastic Composite Pipe (TCP).

Global quality assurance and risk management company DNV GL defined their F119 recommended practice (RP) for use with pipelines in offshore oil & gas (O&G) operations.

Following an extensive and challenging testing programme, the product qualification covers m-pipe® for dynamic surface to seabed applications. Successful certification with DNV GL’s third-party verification highlights the durability of m-pipe® and its constituent materials.

There is a growing interest in thermoplastic composites for subsea applications, due to their corrosion resistance and ability to handle sour service and many of the aggressive chemicals used in the oil and gas industry.

Recent deployments for m-pipe® include a 2.5km flowline development by Tullow Oil in West Africa.

-

-

05 February 2018