Venetian middle-distance runner Miro Buroni has created and developed Pleko, customized and revolutionary athletics track shoes (in jargon, spike shoes) with innovative features in terms of production technology and material.

To create Pleko, Miro made use of the skills and support of two companies: Diadora for historical analysis and design and CRP Technology for the manufacture of the outsole-midsole and ribbing, through professional 3D printing and Windform® SP Carbon fiber filled composite material.

The creation of Pleko started with the three-dimensional scan of the athlete's foot. This step was followed by the biomechanical analysis of the act of running and footing through the 3D foot scan.

When the project was ready to became reality, Buroni decided to use additive manufacturing to build the supporting structure of the Pleko. “After a brief research - Buroni states - it immediately became clear that CRP Technology was the perfect company to realize my project, and that one of CRP Technology's top composite materials, Windform SP, was the appropriate construction material."

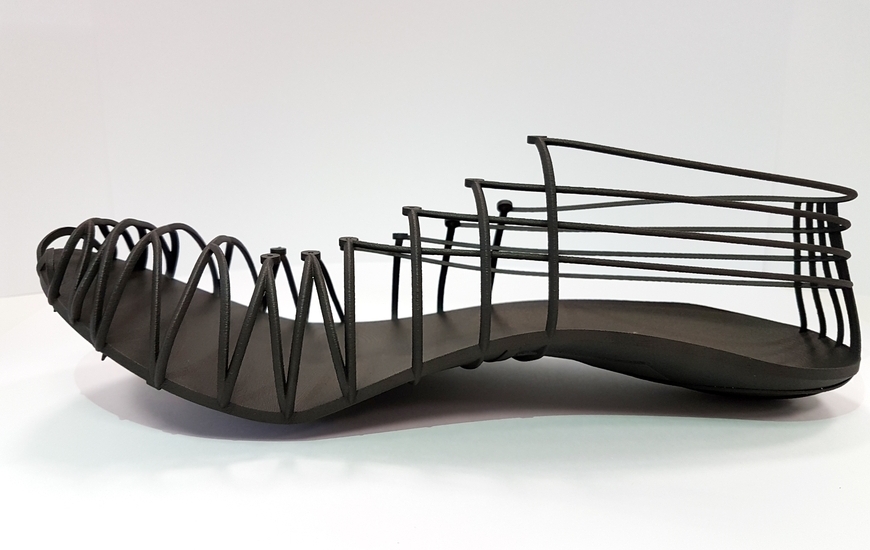

CRP Technology manufactured as single unit Pleko’s outsole, midsole, ribs and pins.

Ribs are originated from under the outsole, in correspondence with the lines of maximum effort during the track race.

Thanks to the ribs, the structure in Windform SP embraces the athlete's foot “like a cage”, which envelops the foot and facilitate improvements in the running technique. The ribs are responsible for carrying the kinetic energy releases from the biomechanical movement during the track race, and preventing its dispersion. The sock-like upper is almost completely detached from the structure and responsible for protecting the foot.

“Thanks to the pins under the outsole - adds Miro - the “cage” in Windform SP allows the athlete to develop as much strength as possible, without losing energy. I positioned the deepest pins in the points of superior pressure of the feet against the ground. I also put smaller studs in other parts of the outsole: these studs are on a equal basis essential for the stability of the track shoes.”

Ph. Pleko track spikes functional prototype with outsole, midsole, pins and ribbing 3D printed by CRP Technology as a single unit in Carbon fiber filled composite material Windform SP. Courtesy Miro Buroni/CRP Technology

-

-

08 October 2021