Third appointment with the column "Academic world" born from a collaboration between Portale Compositi / Composites Portal and the DICAR of the University of Catania. The column, dedicated to the most current issues in the composites sector, now proposes an exploration of recyclable epoxy resins.

by GIANLUCA CICALA* AND CLAUDIO TOSTO**

The carbon fiber market growth is constant with a demand expected to reach 194 ktons by 2022 and a global market increase to $48.7 billion. The incremental use of carbon fibers is due their ability to conjugate superior mechanical resistance and lightness that led to a wide and increasing use in aerospace and automotive.

The latter sector is or high relevance for the recycling issue. The development of car model like the BMW i3 and i8 increased the probability of ending with tons of carbon fiber composites in the landfill. This might rise several problems because the 2000/53/EC EU Directive, entails a 95% recovery and 85% recycling extent of total EoL vehicle weight by 2015 and, at the same time, tends to limit the use of nonmetal components. Therefore, on one side the use of light carbon fiber composites is favored while, on the other side, the materials must be developed to avoid impact on the environment and, as such, it poses a severe limitation to the use of non degradable polymeric system such as all the routinely used thermoset resins. From the practical point of view this would impact greatly on the final performance of the composite’s parts.

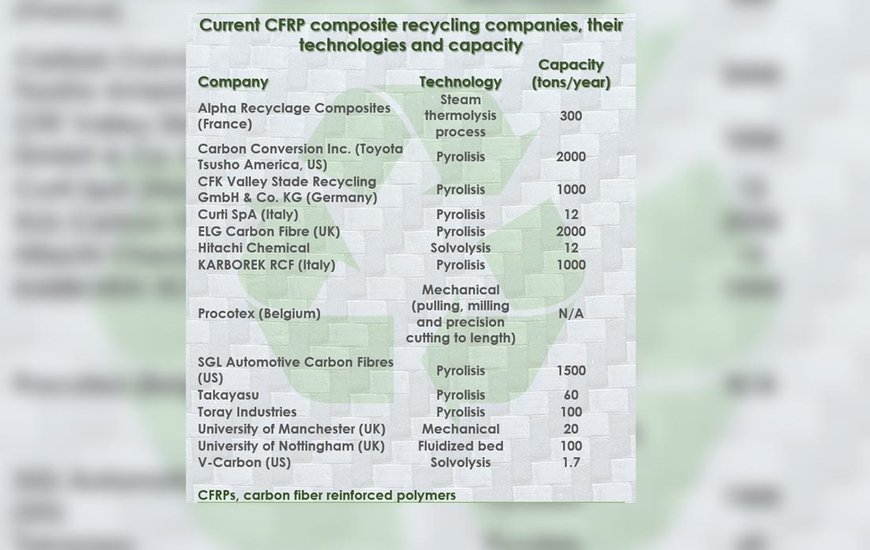

For these reasons, the industry and the academia turned its interest toward novel approaches for recycling of thermoset composites or, in the most innovative solutions, to fully re-use matrices despite their thermoset nature. Recycling of thermoset composites, in its readily available industrial approach, is based on burning of the matrices with recovery of the valuable carbon fibers. Elg Carbon Fiber Ltd is one of the main players in the filed with a reported capacity of 2000 tons/year and with the offer of several products under the tradename Carbisio ranging from milled fibers to non-woven mats and tow.

The table in the picture (by Giorgini et al, Current Opinion in Green and Sustainable Chemistry 2020, 26:100368) reports the capacity for several producers active in this business nowadays. This approach allows to recover carbon fibers and, in some case, energy from the matrices but it has several drawbacks: it does not allow to recover and reuse the polymeric matrix and, as such, it is not a sustainable approach in the long term; it degrades the carbon fiber properties and surface thus leading to obtain a recovered reinforcement with limited applications and lower value compared to virgin carbon fibers.

To overcome these limitations several approaches have been developed based on the common ideas to use chemical recycling to tailor the depolymerization of the thermoset matrix down into usable molecules. This approach, named chemical recycling, relies on the use of severe solutions and processing conditions to enable covalent link breakage and, as such, results in the conversion of the thermoset network into simple oligomers or molecules. Therefore, with this approach the products obtained from the matrices can be used as raw chemical reagents and, to some extent, re-used with additional synthetic steps to produce new polymeric systems. This approach has the advantage to lead, potentially, to tailored recycled products with intact properties. However, the whole process is complex and requires many synthetic steps which might overall impact on the environment due to the use of solvent and many chemical reactions. Companies like Adherent Technologies optimized a proprietary process for chemical recycling which is operative since a decade now and, most recently Vartega developed its proprietary solvolysis approach.

Apart from these solutions well focused on treating existing composites a more radical approach foresee to innovate the chemistry of the thermoset matrices to enable easy and straightforward recycling approach. The pioneer in the field was the company Connora Technology that introduced their patented Recyclamine curing agents some years ago. The recyclamine curing agents are a unique hardener embedding cleavable groups in their structure that can be selectively broken in mild condition leading to transform thermoset into readily usable thermoplastic. The carbon fibers, due to the mild conditions used, are left unaltered thus keeping their initial value and properties. Recently, this approach was tested on hybrid natural/carbon fiber composites developed for HPRTM and resin infusion demonstrating its feasibility even when degradable reinforcing fiber made of flax are used (see Cicala et al, Hybrid Biobased Recyclable Epoxy Composites for Mass Production POLYMER COMPOSITES—2017 and also Cicala et al, Hybrid composites manufactured by resin infusion with a fully recyclable bioepoxy resin Composites Part B 132 (2018) 69e76).

Connora Technology recently sold its technology to Aditya Birla Chemicals planning to expand the business opportunities. Similar approaches as the one proposed by Connora Technology are under intensive development as demonstrated by the Ecoxy consortium that aims to develop bio-based, recyclable, reshapable and repairable reinforced thermoset composites. This approach is based on the further development of the vitrimers approach that now companies like Mallinda are trying to exploit on commercial level.

The analysis of the state of art reported briefly here justify the title “a never ending story”. Even if thermosets have been criticized for their sustainability, thanks to the clever reaction and research of several groups in the world, the future seems bright wit the new possibilities offered by new chemical reagent that might transform thermoset into a never ending usable product. For sure more research is needed and care should be given to the increasing use of raw materials from renewable and sustainable sources but, as story demonstrate, the composite’s and chemical’s people have the momentum to react and develop new strategies and products.

_________________________

* Professor of Materials Science and Technology (University of Catania)

** PhD Student Polymers and Composites Lab (University of Catania)

-

-

03 November 2020