Sicomin, the formulator of high-performance epoxy resin systems including the market leading GreenPoxy® bio-resin range, announced its latest collaboration with carbon composite recycling leader Fairmat. The two French specialists in sustainable composites have joined forces to create an optimised internal stiffener for a new state of the art body scan scale.

With immediate effect, Sicomin will supply production volumes of FireGreen 37 fire-retardant bio-epoxy that Fairmat will use to press mould a 100% recycled CFRP chip structural reinforcement plate.

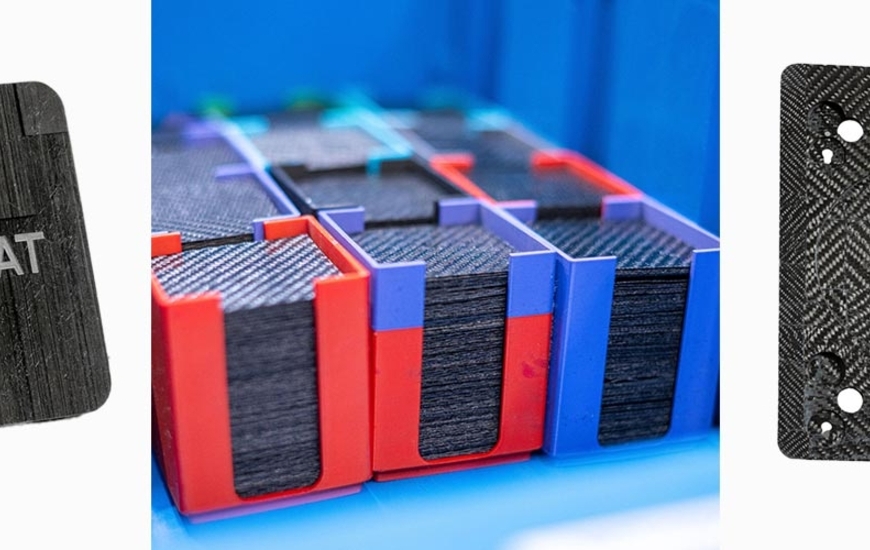

Fairmat uses advanced mechanical processes, robotics and AI, to repurpose high-value, carbon fiber waste streams from leading composite industry OEMs and Tier 1s including Hexcel. For this product, Sicomin FireGreen epoxy resins are combined with the recycled carbon composite materials in an automated moulding process to create a lighter and more structurally efficient internal stiffener for the digital body scan scale.

Fairmat has selected FireGreen 37 resin for the new component after validating its performance in the new production process. Sicomin resins have demonstrated remarkable compatibility with the recycled carbon composite produced by Fairmat, enabling fast wet-out of the pre-cured chips that are robotically positioned into the component mould before press curing. Sicomin also provide quality control documentation that integrates with Fairmat’s Fairtrack Manufacturing Execution System (MES), allowing the rapid, energy efficient conversion of prepreg carbon waste into traceable, lightweight, second-generation carbon fiber materials with validated mechanical performance.

-

-

13 July 2024