Over the past year, Schneider Electric has embarked on a large-scale Industry 4.0 implementation across its worldwide operations.

Named the ‘Smart Factory’ project, the company is strategically deploying cutting-edge technologies and the benefits of the Industrial Internet of Things (IIoT) to drive process optimization. Designed to increase operational efficiency and reduce costs for its customers, the initiative has been rolled out to every factory across the globe with each plant challenged to embrace innovation and drive digital transformation.

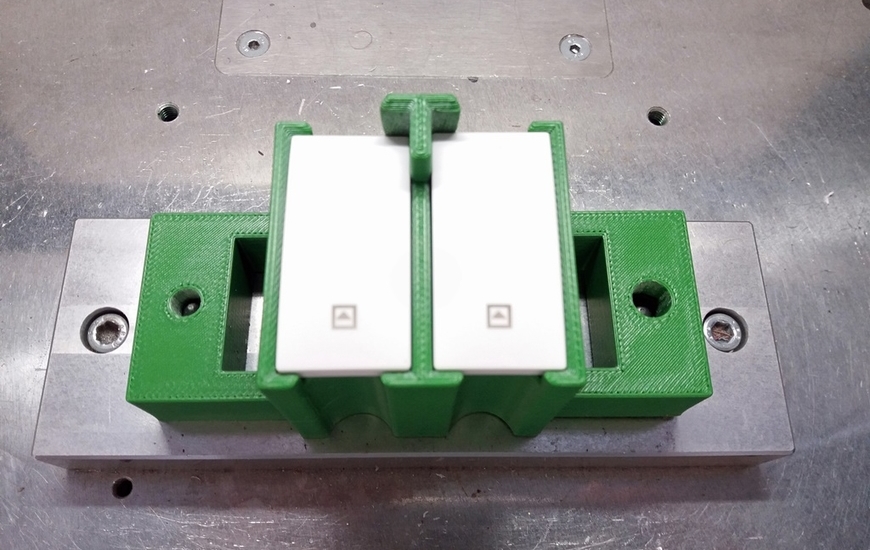

One of the company’s shining lights has been the Puente la Reina plant in Navarra, Spain, which has strategically adopted Stratasys FDM additive manufacturing throughout its production process. The plant is reporting significant efficiencies across its tooling operations in particular, which has led to the management team receiving high-level recognition within Schneider Electric.

In fact, the Puente la Reina plant was recently named winner of the internal European-wide ‘Smart Factory’ Schneider Electric competition – recognizing the acceleration of the plant’s Industry 4.0 transformation for the vast quantities of 3D printed manufacturing tools produced, the outstanding time and cost savings achieved, and newly optimized supply chain efficiencies.

“In the past year, using Stratasys FDM additive manufacturing we’ve achieved a saving of about €20,000 in the production of assembly-line tooling alone, which has easily paid off our original investment in the F170 3D printer,” says Manuel Otamendi, Industrialization and Maintenance Manager – Global Supply Chain at Schneider Electric’s Puente la Reina plant. “With this technology we’re able to produce new high-performance production tools in just one day, whereas it would have taken at least one week to outsource the same tools previously. This crucially reduces our dependency on suppliers and gives us much more control over tool production, which has increased the overall flexibility of our manufacturing process and accelerated our time-to-market for many products.”

-

-

02 July 2020