by VLADYSLAV MIKHNYCH, ANA PAVLOVIC, MARCO BERTOLDI, CRISTIANO FRAGASSA*

Some of the most advanced solar transport applications involve the inclusion of solar cells directly on fiber-reinforced composite panels. This design choice is aided by the fact that the 'encapsulation process' used to build up the solar panel is not very distinctive to the layering procedure applied to manufacture composite parts.

However, the conversion photovoltaic (PV) efficiency remains the key factor which decreases as the panel temperature increases. That is why, knowing the temperature of the solar cells is essential. With such a scope, this research analyzes the heat distribution, layer by layer, of five PV laminates investigating the impact of layup design changes in terms of thermal behavior and efficiency. The solar cell layups included an extremely transparent polymer front sheet (ETFE), a silicon cell surrounded by an encapsulant on both sides (EVA), an insulating polymeric back sheet (PET), taped to a very thin carbon fiber reinforced polymer (CFRP) support.

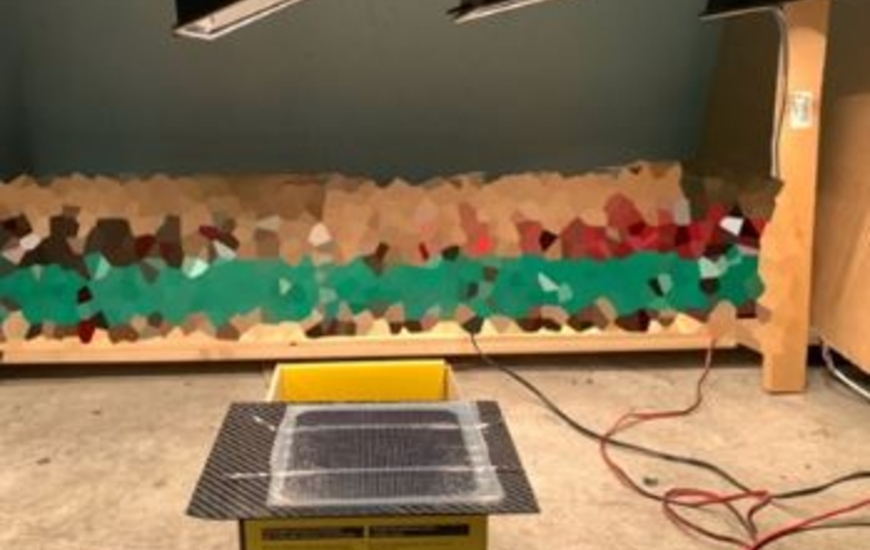

These laminates can efficiently represent, e.g., the roof of top-class solar vehicles. Regarding the research plan, at first, a detailed Finite Element (FE) thermal transient analysis was implemented for each layout using ANSYS Workbench®. Large efforts were addressed to define the correct assumptions regarding the boundary conditions (e.g. heat losses of each layer by reflection and convection). Similarly, the mechanical and thermal properties of all materials were precisely defined by means of the scientific literature. At second, experiments were also performed with the scope to validate the numerical models.

Specifically, Infrared Thermography (IRT) measurements were carried out by a thermal camera under standard conditions (1000W/m2 irradiance at 25°C) allowed to detect the temperature evolution of solar panels over time. Based on the achieved results, an extremely accurate model (>99%) for estimating the steady-state temperature of a photovoltaic module was developed. Most importantly, it has been shown that the materials choice and layer thicknesses can dramatically affect solar cell temperature (up to 3-5 °C) and performance (up to 2-3% lost in efficiency).

Thus, the present numerical model is highly promising as it gives an opportunity to optimize the layup design of solar cells, selecting the best materials for efficient cooling of solar cells and determining the perfect working conditions for PV laminate specific stratification.

* Advanced Mechanics and Materials, University of Bologna

-

-

27 July 2021