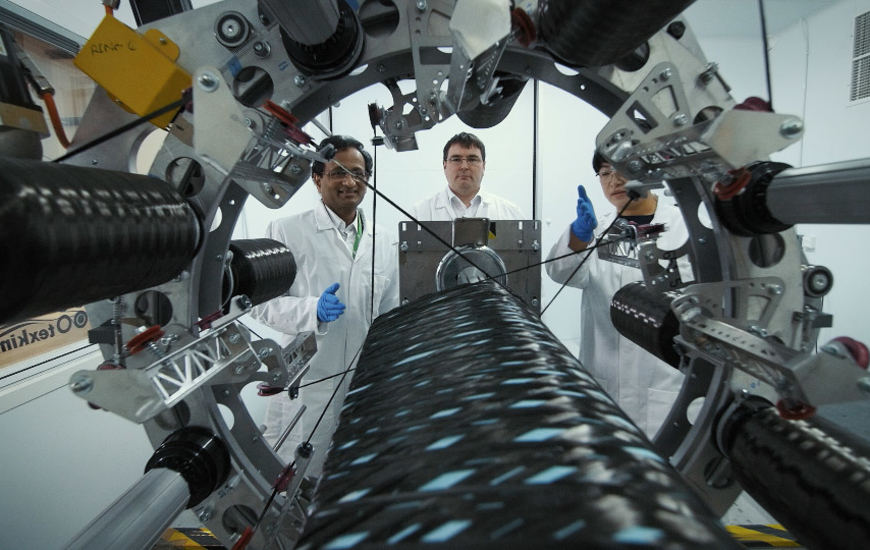

A new machine designed to wind carbon fibre into lightweight parts for the automotive and aerospace industries has been developed by Cygnet Texkimp and The University of Manchester.

The 3D Winder is one of the world's first robotic 3D winding machines capable of making complex parts such as fuel pipes, cant rails and aeroplane wing spars. It can also be adapted to produce components for other markets including wind blades.

It is the result of a two-year Innovate UK Knowledge Transfer Partnership (KTP) between the Northwich-based manufacturer and The University of Manchester’s School of Materials to develop a new way of manufacturing composite components cost-effectively in high volumes and at high speeds.

A production-scale version of the 3D Winder is now being used to carry out advanced trials with international part manufacturers including the creator of lightweight carbon fibre structural components for the high-end automotive market.

-

-

05 July 2018