The aerospace industry is shifting toward lighter and more efficient propulsion, and nacelles are becoming active contributors to aerodynamic, acoustic, and thermal performance. ST Engineering MRAS stands out for having already industrialized automation and digital integration, moving beyond material innovation alone.

With decades of composite experience, the company delivers certified, rate-capable processes for fan cowls, inlets, and thrust reverser structures across major commercial and defense platforms. Engineering and manufacturing operate as a unified system, ensuring design-for-manufacture maturity and full compliance with FAA, EASA, TCCA, and CAAC standards.

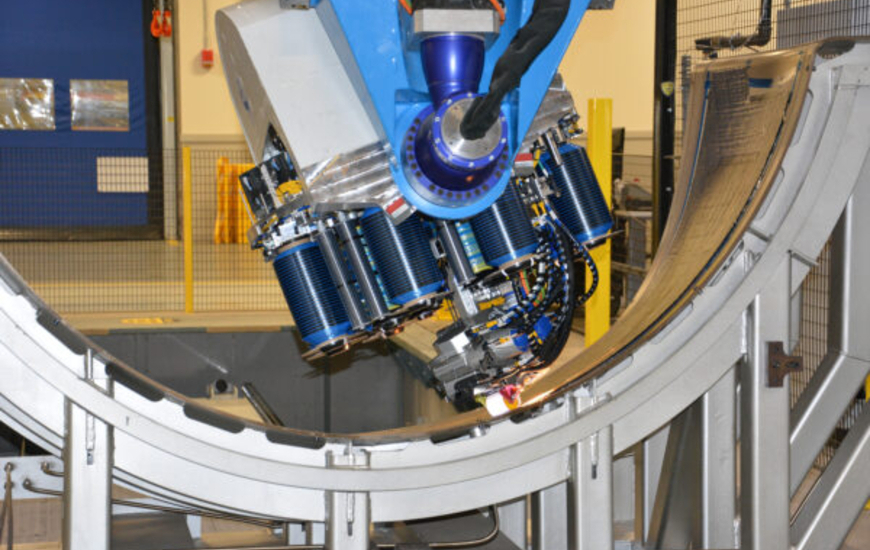

Automation is a strategic enabler: AFP systems build and inspect components simultaneously, while robotic operations support tool cleaning, acoustic drilling, assembly, and predictive facility inspections using acoustic, thermal, and LiDAR sensors.

The cornerstone is the digital thread. Ten autoclaves, ovens, and CNC machines share centralized controls that automatically record every cure and machining cycle, producing complete digital records that accelerate certification, strengthen traceability, and enhance maintenance planning.

MRAS’s industrial maturity spans programs such as Boeing 747, 767, 777X, Airbus A320neo, C-130J, Global 7500, as well as new-generation applications including Archer Aviation and the Jet Zero demonstrator. Automation and digital monitoring also drive sustainability by reducing rework, waste, energy use, and emissions.

The nacelle is viewed as a future propulsion enabler, integrating sensing, electric actuation, thermal management, and digital-twin connectivity to support hydrogen, hybrid-electric, and ultra-high-bypass engines.

Aligned with customer roadmaps, MRAS develops technologies validated directly in production, demonstrating how automation and digital continuity are already reshaping the aerostructures of tomorrow.

-

-

15 November 2025